HSG-city rapid grinding train

- Description

-

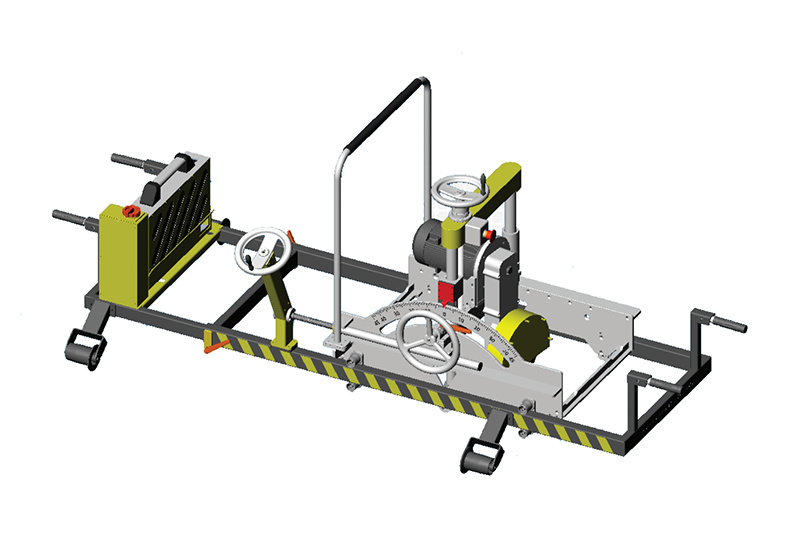

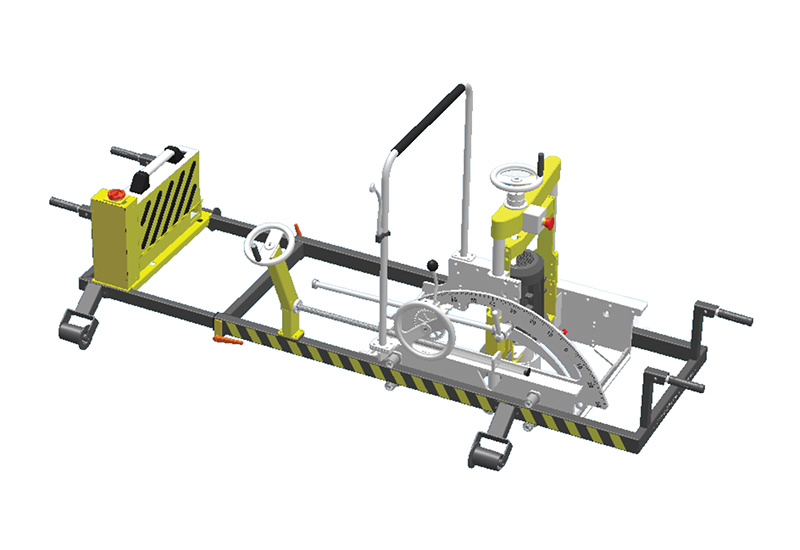

HSG-city City Rail Fast Grinding Vehicle Features

The German Vossloh high-speed grinding vehicle is the only essential for global rail maintenance. This brand has an incomparable generational advantage compared to traditional grinding vehicles. Since 2015, 23 units have been sold domestically, with grinding applications exceeding 20,000 kilometers.

Five Highlights

▶ Fast speed. The grinding speed can reach 60 km/h, and the noise is low.

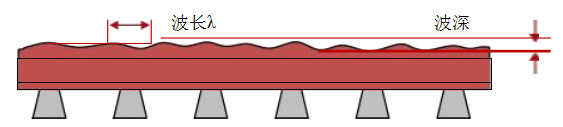

▶ High and thorough wave grinding removal efficiency. At a grinding depth of 0.2mm, a conventional grinding vehicle can complete about 1 km of line grinding per skylight, while a high-speed grinding vehicle can complete 1.5-2 km of line grinding, and can thoroughly remove wave grinding within a wavelength of 1000mm.

▶ Safe and energy-saving. The grinding wheel itself has no power; it uses the friction resistance between the rail surface and the grinding wheel during high-speed travel to drive the grinding wheel to rotate quickly, achieving the grinding effect (professionally known as passive grinding). It will not damage the rail.

▶ Strong applicability. It can be used for pre-grinding of new lines during the construction period and regular grinding during operation.

▶ Easy to transfer. Small size, convenient for transportation between networks using flatbed freight cars, achieving resource sharing.Small limits, easy to transfer, flexibly adapt to the development needs of the network, achieving resource sharing.

▶ Can adapt to the grinding needs of urban railways, subways, light rail, and tram lines, saving procurement funds.

▶ Easy to transfer. Small size, convenient for transportation between networks using flatbed freight cars, achieving resource sharing.Can install onboard rail detection systems and intelligent analysis software.

Intelligent additional functions

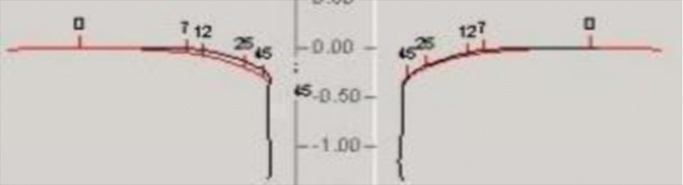

Rail cross-section profile assessment

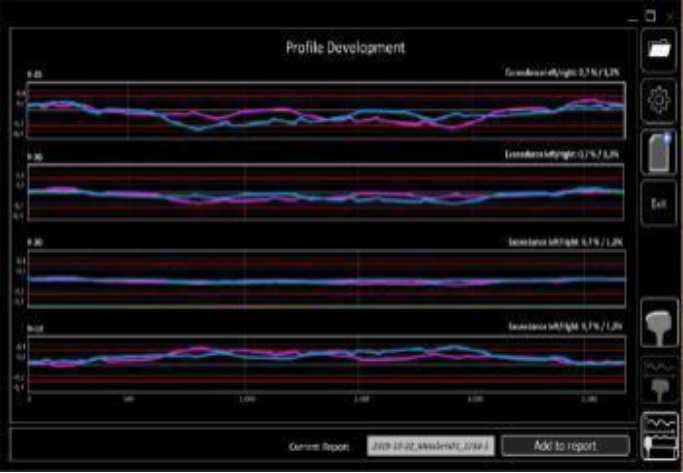

Cross-section profile

▶ During the measurement process, each profile scan will be pre-processed for immediate comparison with the reference profile.

▶ Users can customize reference profile data.

▶ There are three methods for profile assessment.

• Display/view stored profile data for assessment.

• Directly compare the measured profile at any selected position on the track with the reference profile.and display the development of the selected profile coordinates along the track, including calculating/displaying the percentage value exceeding the allowable value.

• Export data to Map l-e and assess the overall condition of the track..

▶ Four coordinates can be selected on the profile to display the profile development at that coordinate. The tolerance range can be adjusted separately for each coordinate.

Figure. Example of rail cross-section profile measurement results in Map l-e software.

Track tread longitudinal profile assessment

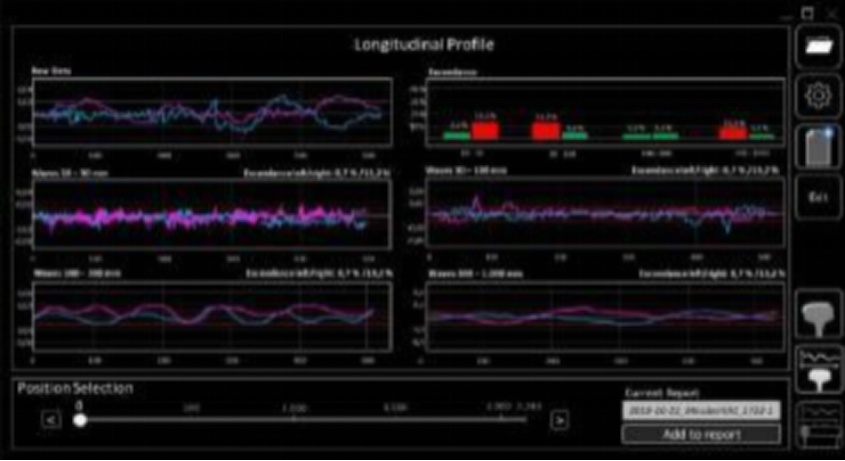

Longitudinal tread profile

▶ According to EN 13231-3,Filter the measured profile into 4 bands. (10-30 mm, 30-100 mm, 100-300 mm, 300-1,000 mm).

▶ Check the filtered profile according to the tolerance bands, each band can be adjusted separately in the settings. The default values are ±0.01 mm, ±0.01 mm, ±0.015 mm, ±0.1 mm.

▶ The proportion exceeding in any wavelength range is represented as a percentage and displayed in a bar chart.▶ The original and filtered profiles can be displayed/reported. Each profile is plotted in the display window, with a display length of 500 meters..

Longitudinal tread profile data can also be exported to Map l-e.

▶ In which the railway condition is mapped to the network for trend analysis or maintenance planning.Figure. Example of longitudinal profile measurement results of rail tread in Map l-e software.

Figure. Map l-e software rail tread longitudinal profile measurement example

Key words:

Related Products

Get Quote